Product introduction

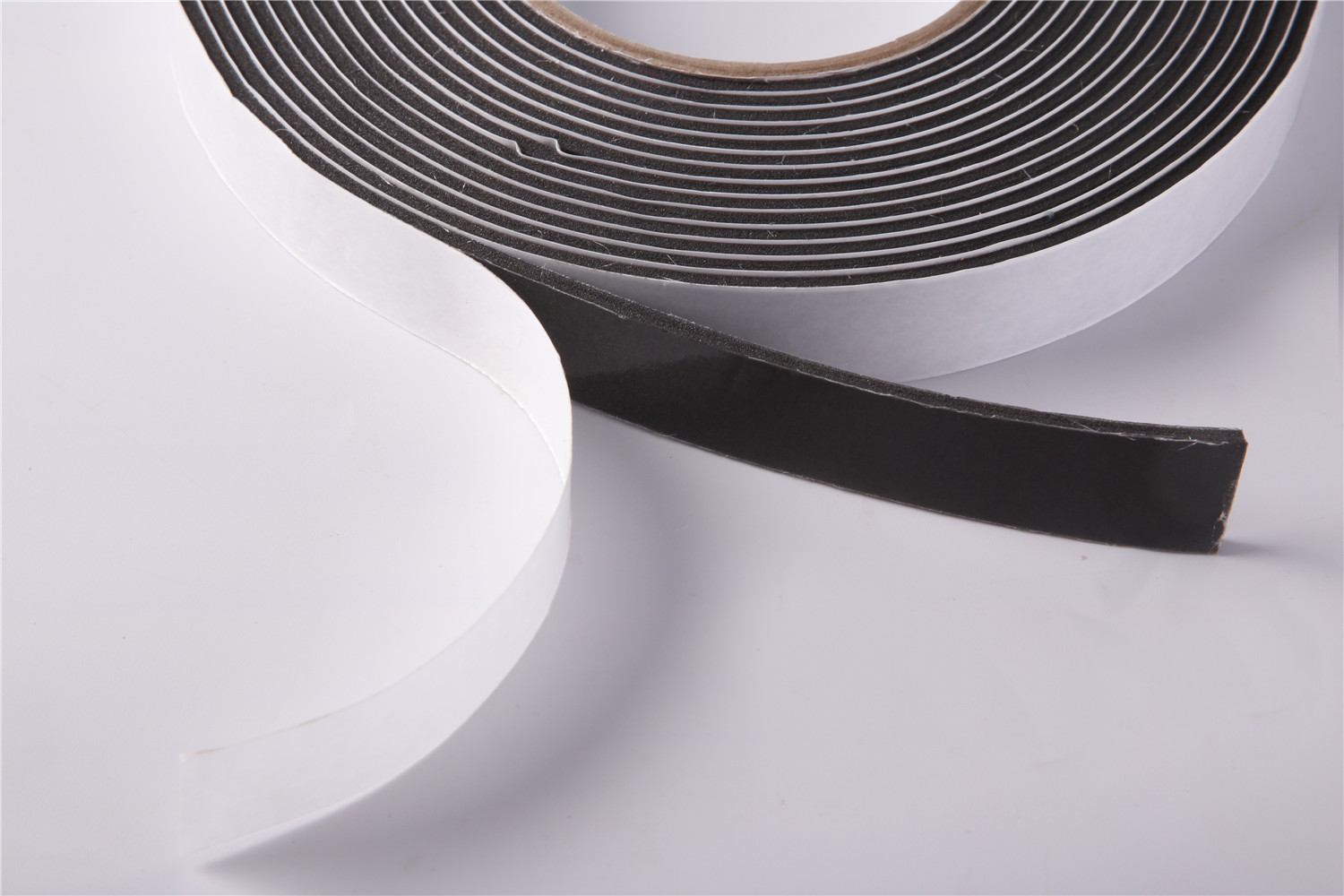

PVC soft black single side sealing strip for door and window is s made by 300-400kg density PVC foam. The foam sealant combines a closed-cell polyvinyl chloride foam substrate with a pressure-sensitive adhesive on both sides.

PVC soft black single side sealing strip for door and window of Polyvinyl Chloride plastic as the main raw material, through high temperature mixing, adding foaming agent, auxiliary agent and other raw materials to make the independent closed-hole foaming material.The foam sealant combines a closed-cell polyvinyl chloride foam substrate with a pressure-sensitive adhesive on both sides.The appearance is smooth,the bubble hole structure is more subtle, press back to play slowly. It has the excellent properties of toughness, heat insulation, sound insulation, high resistance to corrosion, good resilience, small absorption of water, conductive or antistatic.Sanhe foam performance in the window glazing market has made it the good choice in a kind of glazing applications.

Product feature

1.Strong adhesion, excellent shock absorption and crack resistance, sound absorption, and thermal insulation;

2.Good isolation and buffering performance, no water absorption, good shockproof effect;

3.Excellent fire resistance, heat and flame retardant effect, good mechanical strength and electrical insulation;

4.High tensile strength, good elongation, good adaptability to base expansion or cracking deformation;

5.Good stain resistance, easy to clean, special UV treatment, corrosion resistance;

Product application

It is used for flexible connection of building, household, decoration and so on, and is also the best choice of window glass assembly, which is loved by people in developed countries in Europe and America.

Property | Test Method | Value or Rating |

Density: | ASTM D1667 | 300-400 kg/m³ |

Hardness: Shore 00 | ASTM D2240 | 40-55 |

Holding Power: | ASTM D3654/D3654M-06(2011) | >72h |

Initial Tack: | ASTM D3121-06 | 8.2mm |

180°Peel Strength: | ASTM D3330/D3330M-04(2010) | 0.82N/mm |

90° Peel Adhesion: | AAMA 810.1 | 855 N/mm |

Shear Strength: | ASTM D1002-2010 | 0.16N/mm² |

Compression Set: | AAMA 810.1 | 0.7% |

Compression Deflection: | AAMA 810.1 | |

Tensile Strength: | AAMA 810.1 | 400KPa |

Elongation At Break: | ASTM D412 | 100-130% |

Force to Compress : | AAMA 810.1 | 70KPa |

Water Absorption | AAMA 810.1 | 1% |

Flammability | UL-94-2013 FMVSS 302 | HB Pass |

Dynamic Tensile Adhesion: | NTP-11 | 307-365KPa |

Dynamic Shear Adhesion: | NTP-5 | 200-255KPa |

Static Shear Adhesion: Hours 1 psi load* | NTP-57 | 1900+ |

Thermal Conductivity K factor: | ASTM C518 | 0.06w/m•°C |

Migratory Staining of Acrylic Enamel: 200 hours of ultraviolet at 140°F | ASTM D925 | No Staining |

Service Temperature | -- | -40°C to 80°C |

Application Temperature: | -- | 15°C to 50°C |

Resistance(Ba Rebound) | ASTM D3574-H | 21% |